From concept to end product in 6 fast steps without unnecessary iterations

Electronic development working method

Introduction

First meeting

01Over the phone or a nice cup of coffee. We discuss your idea and development plans. Do you want to make an existing product more reliable, smarter, more efficient or cheaper? Or launch an ambitious new concept? You tell me all about your idea and I let you know what the possibilities are and set out the development path. It is a non-binding meeting, ideal for finding out whether we are a good match.

Preliminary assessment (optional)

The first thing I do for cutting-edge or complex products is carry out a preliminary assessment. This makes sense when some aspects still need to be fleshed out because it prevents technical complications further down the development path. It saves you time and money. I identify the critical tasks, study the technical possibilities and review potential risks. You know what you will be getting before we start developing the product.

Functional model (optional)

Sometimes, doubts persist following the preliminary assessment. In this case, I build a functional model (FuMo). This pre-prototype is a simplified version of the electronics for the product. For example, I design the circuit board and the software we need to test functionalities, identify risks and shine a light on the specifications. That way, we know for sure whether the end product will soon work as we want it to —before we even build the first prototype.

How do the optional steps work?

The preliminary assessment and functional model are only needed in very challenging projects. In other words, projects that necessitate very complex electronic tech or in which we need to test customised electronics (in practice, in the lab or on the field) to determine the functional requirements and specifications. When we first meet, I can assess whether these steps are applicable to your project.

Offer

02By this point, all the important specifications are clear. We know exactly how the product is going to work, what the functional requirements and design choices are, and how to deal with environmental conditions, standards and manufacturability, among other issues. Now that we have laid the foundations, I make you a clear offer for the whole development path.

Drawing up the specification document

03The specification document contains all the detailed product specifications. When I say "all" the specifications, I really mean it: even specifications that had not even crossed your mind. From the choice of plug to the dimensions, from the system interface to electromagnetic compatibility. This document is the cornerstone of product development. Writing down the agreements helps us to avoid ambiguities and unnecessary revisions at a later point.

Development

Product development

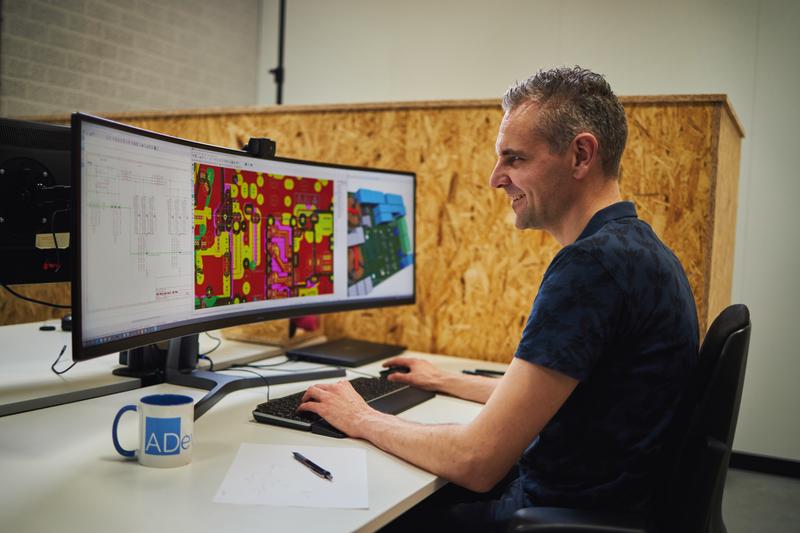

04Now comes the fun part: product development. It starts with plenty of calculations and modelling. I design the electronic diagram and implement it on a circuit board, which I test for all the specifications. This prototype is often virtually identical to the end product. I record the test results in a certification document, which proves that the prototype meets the agreed specifications.

Final tests

05Is the prototype ready? Then it is time for integration testing. In most cases, this can be done on-site at your facilities. Since my prototypes are virtually identical to the end product, you can already have them undergo EMC (pre-)certification. If necessary, I will design a new iteration with minor tweaks. We did it: your product is ready for serial production.

Serial production

06At this point, you may think: now what? You can still count on me. I can assist you with launching serial production or provide ad hoc advice if production issues arise with the electronic design. I can even take care of the whole production process for you in collaboration with a reliable partner.

Do you think I can help you?

Get in touch. I look forward to hearing about your idea.