Power electronics lie at the heart of many products. They are what makes it possible to charge your electric car with electricity from your solar panels or carry out an MRI scan. You can find them in the control systems for train engines and wind farms. In short, power electronics are all around us.

Power electronics

What are power electronics?

What do power electronics do?

You can charge your laptop and your car from the same electrical grid, but each of them needs a completely different level of power. Power electronics allow us to switch, control and convert the energy flow. This holds just as true for consumer products (such as adapters and induction stoves) as for industrial applications (such as induction heating and motor control) and even high-voltage engineering.

The efficiency of power electronics is often higher than 95%, so very little power is lost in the switch. They are readily scalable, lightning-fast, compact, flexible and reliable even in harsh environmental conditions.

Power electronics applications and tech:

Applications of power electronics

- Chargers

- Back-up power supply

- Motor control (direct-drive brushless motors)

- High-voltage power supply

- Power Factor Correctors (PFC)

- Switched-mode power supply

- Wireless charging

- Wireless power transfer

- Induction heating

- Joule heating

- Resonant converters

- Ultracapacitor charger

Interfaces

- Analogue control

- Digital control (microcontrollers, DSP, FPGAs)

- Digital interfaces (Ethernet, EtherCAT, Modbus, Wi-Fi, Bluetooth, etc.)

- Single-phase mains supply

- Three-phase mains supply

Type circuits

- Flyback converters

- Resonant converters

- Forward converters

- Buck converters

- Boost converters

- Multilevel converters

- Full bridges

- Dual-active bridges (DABs)

- Charge pumps

- Resonance-charge pumps

- Amplifiers (classes A, AB, D and E)

- Isolated power supply

Interfaces

- Digital electronics

- Embedded software

- Cooling

- Control technology (analogue and digital)

- Inductive component development

Power electronics: design for manufacturability

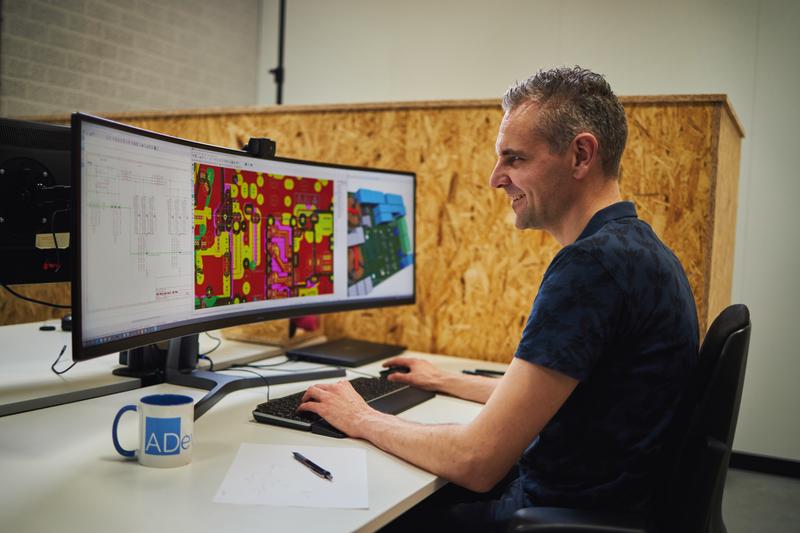

I follow the "design for manufacturability" principle. I already have the final serial product in mind in the development phase. My aim is to create an end product that is safe, works perfectly and can be manufactured efficiently at a reasonable price. For example, I strive to keep things simple and production and distribution timelines short. Focusing on this from the beginning saves money and requires fewer prototypes.

Electromagnetic compatibility (EMC)

Electromagnetic compatibility (EMC)

EMC is an important aspect of electronic development. The European EMC Directive establishes strict requirements for electromagnetic compatibility. These requirements are specific to each product, as the potential for interference depends on the application and location of use. EMC-proof design therefore necessitates in-depth knowledge of technology and physical processes.

I map out the EMC requirements for each product in the development phase. My ample experience in this area means that my designs never come up short. EMC testing can often be conducted on the first prototype.

Power electronics design: robust, reliable and efficient

Does your product have a plug or a battery? Does it control a motor, for example? If so, it contains power electronics. They can be found in a very wide range of products. It is a complex field: a single circuit board can have over a thousand components. All of them need to work perfectly to create a reliable and sound end product. This is why there are several key aspects to my working method.

Power electronics design

Understood. Now what?

Want to find out more? Find out more:

Want to talk to an expert? Get in touch to schedule a non-binding appointment.